Recently, there have been multiple reports of fires, and as the holiday approaches and photovoltaic power plants continue to generate electricity, safety issues need to be given more attention by the industry.

The Beijing Municipal Market Supervision and Administration Bureau has issued the "Electrical Safety Technical Specification for Distributed Photovoltaic Power Generation Systems" for rooftop distributed photovoltaics, which has been officially implemented since April 1st.

The document specifies and specifies that the rooftop photovoltaic system must have component level fast shutdown function through the "Article 6 Electrical Safety Design" specification.

6.2.7 Quick shutdown

The system should have a fast shutdown function. Within 30 seconds after the fast shutdown device is activated, the voltage within the boundary range should be reduced to below 120V, and the voltage outside the boundary range should be reduced to below 30V, with an extension of 305mm from the edge of the photovoltaic array as the boundary.

This is also another key city that has put forward clear requirements for photovoltaic safety applications, following the introduction of safety regulations for component level fast shutdown applications in Dongguan, Shenzhen, Haining and other places.

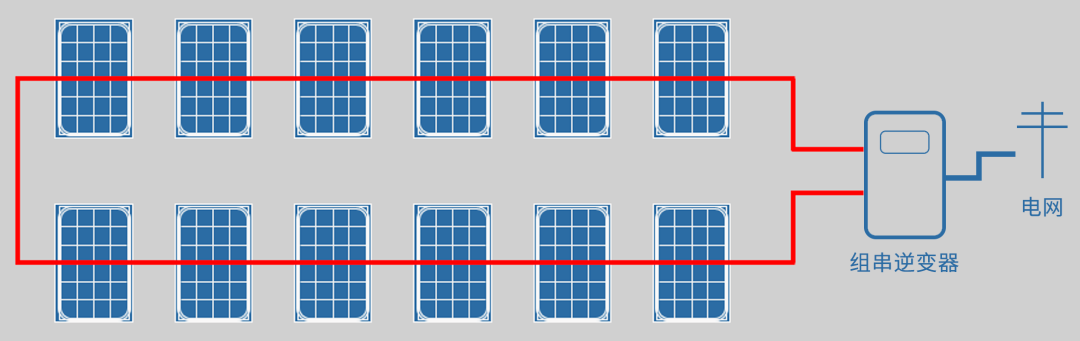

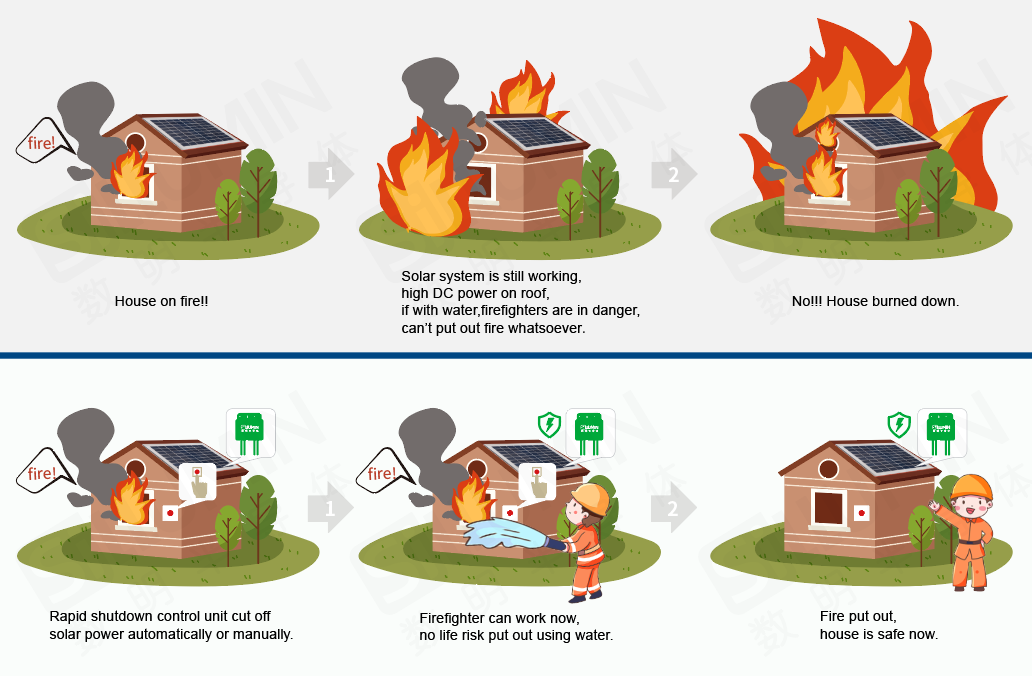

The rescue of accidents at rooftop photovoltaic power plants is very difficult; When a fire occurs, even if the inverter is turned off, due to the conventional components being connected in series hand in hand, there is still a DC high voltage in the photovoltaic array. Using conventional watering to extinguish the fire, the high voltage electricity goes wherever the water flows, making the firefighting work very dangerous and the firefighters cannot take timely rescue measures.

Conventional firefighting methods such as fire extinguishers, fire hydrants, and fire truck hoses are simply not applicable; Chemical dry powder fire extinguishing agents can be used, but their ability is limited, making it seem like a drop in the bucket when the fire gets bigger. If the photovoltaic power station also comes with energy storage devices, there is a risk of explosion.

In the absence of component level fast shutdown function in photovoltaic power plants, firefighters can only handle the aftermath after the combustible materials are burned out and the fire on site naturally extinguishes.

Component level fast shutdown function

Addressing the 'risk of firefighter rescue'

The document released by the Beijing Market Supervision Administration pointed out that the system should have a fast shutdown function. Within 30 seconds after the fast shutdown device is activated, the voltage within the boundary range should be reduced to below 120V, and the voltage outside the boundary range should be reduced to below 30V, with an extension of 305mm from the edge of the photovoltaic array as the boundary.

The quick shutdown function is an effective and safe way to deal with DC high voltage problems in photovoltaic power plants in the event of emergency faults (especially fires), which can directly and effectively avoid the risk of electric shock during the rescue process+

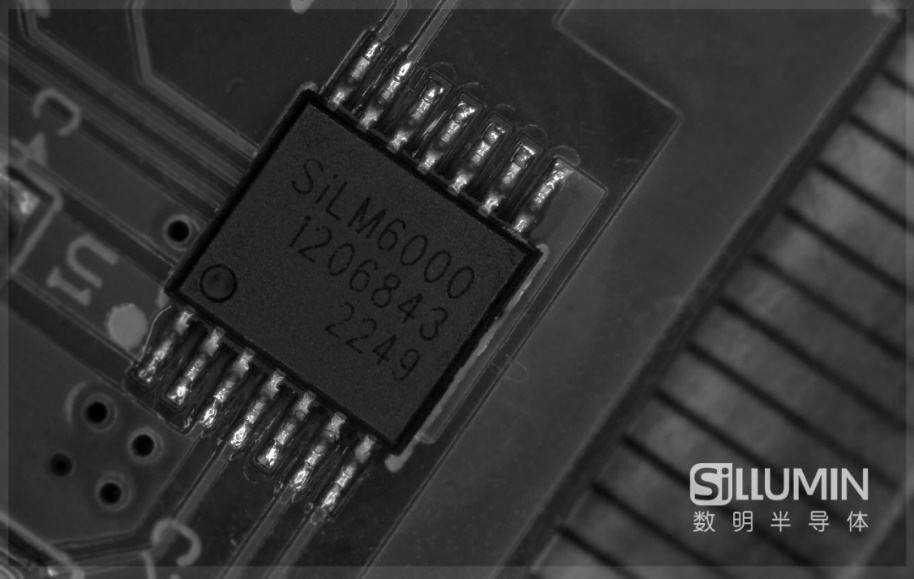

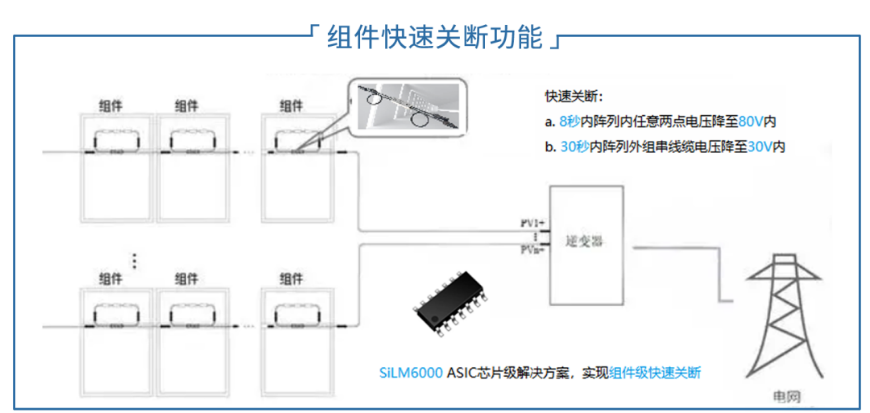

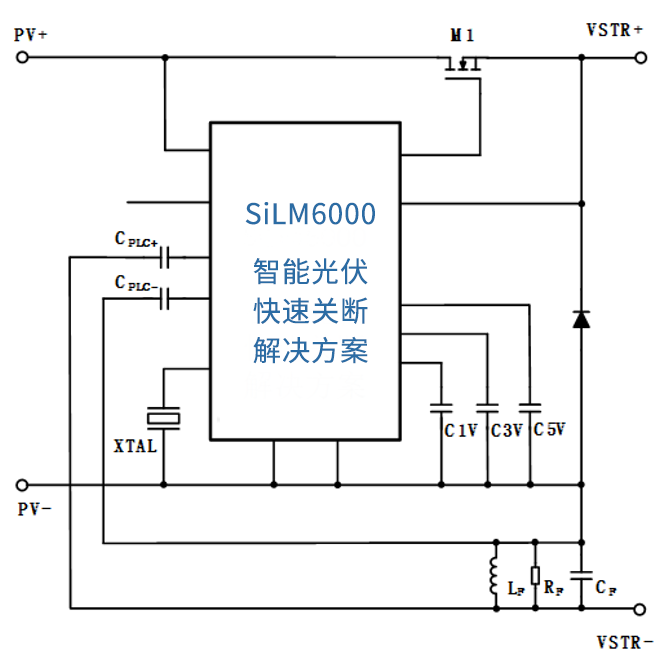

The photovoltaic safety shutdown "SiLM6000" chip solution of Suming Semiconductor can achieve the function of controlling component level fast shutdown. The component level fast shutdown product based on the SiLM6000 chip solution can be remotely or manually shut down, allowing each photovoltaic module to output at a low voltage of 1V in the shutdown state. This enables the module to achieve low voltage output within 8 seconds within the photovoltaic array range (i.e., the voltage at any two points in the array is lower than 80V), and the string voltage on the cable drops below 30V. Thus eliminating the DC high voltage of photovoltaic power plants and solving the problem of "difficult rescue in case of fire" in rooftop photovoltaic power plants.

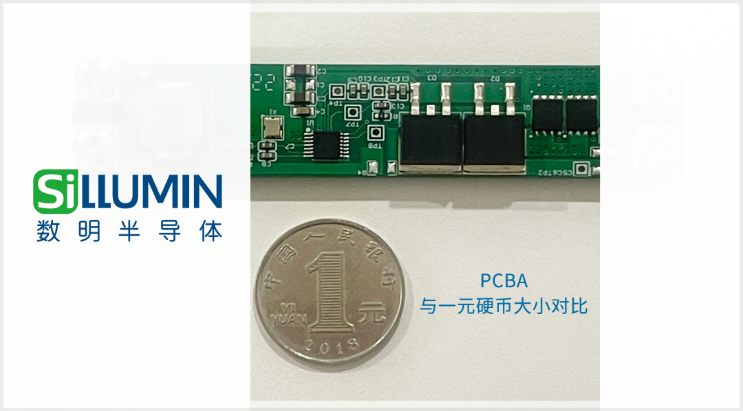

The SiLM6000 chip is a highly integrated ASIC solution that integrates functions such as power management, SunSpec protocol PLC signal analysis, logic control unit, MOSFET driver, and 1V low voltage output in the off state. It is small and fully functional.

Based on the SiLM6000 chip solution provided by Suming, users can achieve rapid design, sampling, and mass production. The fast shutdown product can be applied to 210 high current components (compatible with 182 components downwards), and has the advantages of small size, high cost, and high reliability.

Except for special scenarios such as fires, when distributed photovoltaic power plants in high-speed, highway, river, and other scenarios experience wire breakage due to external forces or accidents, the fast shutdown device will quickly turn all component outputs of the string that have wire breakage faults into 1V low-voltage output within 8 seconds, avoiding the expansion of secondary accidents caused by electric shock to personnel.

In addition, the Digital Intelligent Photovoltaic Solution also has functions such as intelligent optimization and data collection monitoring for customers to expand. Integrated photovoltaic module level MPPT maximum power point tracking can optimize the power output of each module by tracking the maximum power point of the photovoltaic module, eliminate module mismatch, recover power generation losses, and improve the distributed photovoltaic system's power generation by 3% to 25%; Solve the current mismatch problem caused by component installation differences, obstruction, orientation differences, and component attenuation differences throughout the entire life cycle of the photovoltaic system, fully tap the power generation potential of each component, and improve the revenue of the photovoltaic power station.

Photovoltaic energy has become an important way to improve the climate environment and optimize energy structure. The transition from traditional "energy extraction" to "energy manufacturing" has achieved the combination and upgrading of China's manufacturing advantages and advanced technologies. The development of photovoltaics has been closely linked to the development of China and the production and life of millions of households. How to ensure the "safety" of photovoltaic power stations is receiving high attention from the entire industry. Shenzhen, Dongguan, Haining, and Beijing have made clear regulations on key safety issues such as component level fast shutdown.

As always, Suming Semiconductor will continue to deepen its efforts in the fields of smart energy and pan industry, and develop more and more excellent chip solutions with "high integration, high reliability, and high cost-effectiveness" to safeguard new energy.

Contact Us

Obtain SiLM6000 chip samples for free